It’s good to have great weeks. Qnect had a successful week at this year’s NASCC: The Steel Conference! Seeing our customers, partners and other members of the steel industry is always a highlight at this annual event. In addition, we gained more customers, announced an investment in Qnect by Nucor, enjoyed the Thursday Conference Dinner and soaked in the positive energy so many were feeling in the Baltimore Convention Center.

If you were able to join us, you might have been one of many that sat in on our product demo “Using Qnect for Value Engineering and Project Optimization” and our workshop “How to Leverage Tekla + Qnect for Esti-modeling.”

During the conference, we had literature that highlighted our work with the Seattle-Tacoma International Airport, The Harper and Rock Hill School as well as quality microfibers for our booth visitors. We kept a few of the Qnect Microfibers back at HQ so if you would like some let us know and we’ll be happy to send a few out to you.

For those that did not make the trek to Baltimore, you missed our 10×20 booth where we offered demonstrations of QuickQnect and B+Op (read about B+Op here).

Several people have already requested a personal demo either because you were unable to get one at the booth or because you needed more team members to sit in with you. For all of you, you can request a personal demo by filling out this form or contacting Christian Erickson directly at Christian@Qnect.com and we’ll arrange a time.

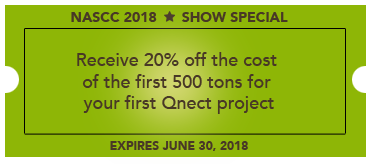

NASCC 2018 Show Special

For even bigger news…our show special has been extended to those that were not able to attend the event. That’s right, even you can get the show special. You receive 20% off the cost of your first 500 tons for your first Qnect project when you upload and connect your model before June 30, 2018.

Visit our Facebook page to see the photo album from the conference, including a few pictures of the Booth, the Product Demo and Workshop.

To be the first to see our news and announcements below follow on our social pages:

We look forward to seeing you throughout the year and in St. Louis for #NASCC19! And…a special thanks to AISC (American Institute of Steel Construction) for another great event.

About AISC: American Institute Of Steel Construction

The American Institute of Steel Construction (AISC), headquartered in Chicago, is a not-for-profit technical institute and trade association established in 1921 to serve the structural steel design community and construction industry in the United States. AISC’s mission is to make structural steel the material of choice by being the leader in structural-steel-related technical and market-building activities, including: specification and code development, research, education, technical assistance, quality certification, standardization, and market development. AISC has a long tradition of service to the steel construction industry providing timely and reliable information.

About NASCC: The Steel Conference

NASCC: THE STEEL CONFERENCE is the ideal place for structural engineers, steel fabricators, detailers and erectors to learn about structural steel design and construction, to interact with their peers and to see the latest products for steel buildings and bridges. The Steel Conference offers more than 100 technical sessions and is the premier educational event for structural engineers, fabricators, erectors and detailers. In addition to practical seminars on the latest design concepts and construction techniques, the conference offers an extensive trade show (featuring products ranging from structural software to machinery for cutting steel beams) and plentiful networking opportunities. It’s a once-a-year opportunity to learn the latest techniques, see the most innovative products and network with your peers and clients.